Project Development ٩(•̤̀ᵕ•̤́๑)

- jiamin20

- Feb 18, 2022

- 7 min read

Updated: Feb 18, 2022

And finally, the last blog... 🥳🥳🥳

1. Our team Chemical Device

As we all know that the world has been hit by the pandemic since 2019. Due to the pandemic, sanitization of objects has been more important than ever. The pandemic has drilled into us the importance of washing our hands regularly, and spurred us all to clean the surfaces in our home with renewed vigour. But have we given enough thought to the cleanliness of the thing most of us use every day – like our phones?

So how does our handphone sterilisation box resolve the issue? Instead of using alcohol swabs to clean your phones, our sterilisation box sanitizes phones thoroughly by using UV light that entirely encompasses the phone in the box with no obstructions and does not leave any stains or watermarks that alcohol swabs leave. It is easily operated and takes less than a minute to sanitize your phone thoroughly. This way you would not have to wait long to be able to use your phone again!

Here's the final sketch of our product!

2. Team Planning, Allocation, and Execution

AJ SQUARE

Shim Jihyun - CEO (Team Leader)

Yeo Jia Min - CFO

Aqilah Cheng COO

Prior to the start of product development, we had to identify the materials and components required and for that purpose, we used a BOM Template to help us with that. The Bill of Materials (BOM) as shown below is a list of the raw materials, sub-components, parts, and the quantities of each needed to create our prototype.

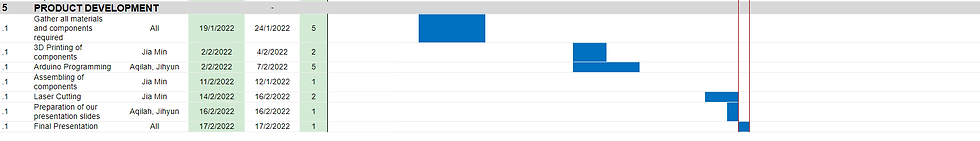

Next up, the Gantt Chart is a type of bar chart that illustrates a project schedule. As shown below, the whole project started on 10 October 2021 and ended on 17 February 2022. The Gantt Chart also showed the allocation and execution of tasks. All of my group members took turn to lead each task and the workload were evenly distributed.

Gantt Chart (Planned):

Gantt Chart (Actual):

For the actual Gantt chart, the only changes that we made to the Gantt chart was the last section which was on Product Development. Apart from that, section 1-4 remains unchanged.

3. Design and Build Process

Part 1. 3D Printing of hinged lid and the base (Done by Jia Min)

To come out with the sketch, I used iPhone 13 Pro Max as a size guide since it is one of the bigger phones in the market and we wanted our product to cater to as many handphone models as possible, regardless of the size of the phone. After coming out with our final sketch, we had to replicate it onto Fusion 360.

These parameters are the original dimensions of our product but due to time constraint, we decided to just 3D print the components at 70% of its original size. It would take up to 8 hours printing both components if we print them at its original size.

Didn't manage to take a proper hero shot but here's a picture of me removing the support from the lid.

Part 2. Soldering of Wires (Done by Jihyun, Aqilah)

We soldered our wires to join them together and the table shown below summarises what we soldered.

Hero Shot of Aqilah and Jihyun soldering!

Part 3. Programming of Weight Sensor (Done by Jihyun, Aqilah)

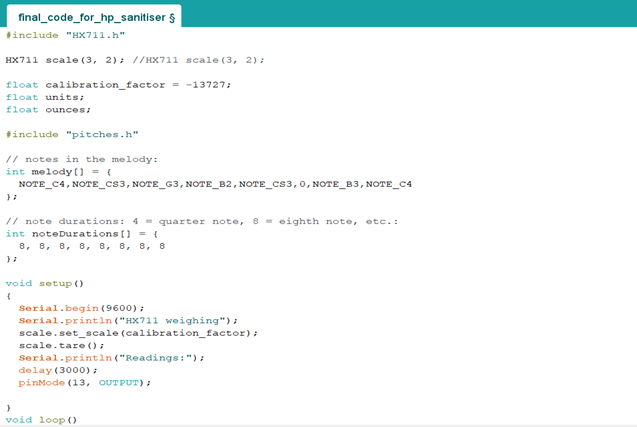

1. Calibration Code

Using this calibration code for a 5kg load cell scale sensor we found online after setting up the maker uno, we calibrated it to 250g which was the maximum load that we planned on setting. We first had to download and include the HX711 libraries to the Arduino. We then clicked on the serial monitor icon at the top right hand corner of the screen to view the weight and calibration factor readings. To increase the desired weight during calibration, we entered ‘a’ while to decrease it enter ‘z’. Once we were satisfied with the calibration, we noted down the calibration factor.

2. Weight Measurement Code

With the calibration factor we derived earlier, we added it into another source code (shown above) to ensure that our calibration has been done accurately. When correctly calibrated and the code is uploaded, the weight sensor will measure the weight of the object placed on it. We tested out our calibration factor and since there was a weight reading, our calibration has been done correctly and we can move on to our final code.

3. Final Code

This is our final code for our UV Light Handphone Sterilization Box. Due to space constraint, instead of having an extra led light and timer outside the box to signal the completions of sterilisation, we decided to add in our own melody into the code to signify the end of the sterilisation. We also coded our sterilization box so that the UV light would only light up when it senses weight.

3a. Fairy Lights (Substitution of UV Light Bulbs)

Since our fairy light was connected to pin 13, our digitalWrite high and low are at pin output 13 as well to send the signal to the fairy light accordingly. The delay of 20000 essentially translates to the fairy light staying on for 20 seconds before it dims down. However, the fairy lights will on be turned on when a weight of more than 0 is detected on the weight sensor. Based on our research, we found out that 20 seconds are sufficient to kill 99% of germs, thus why 20 seconds were chosen. The exit needs to be written at the end to indicate that the whole Arduino system can stop after one round.

3b. Melody

These are the codes for tone melody. The specific notes and their duration has to be clearly specified. Once the fairy lights dim down, the melody will play once to signify the end of the sterilisation.

Hero shot of Aqilah working on the code!

Part 4. Laser Cutting (Done by ME, Jia Min)

Initially, we did not have plans to laser cut as we already decided to use plastic sheets for the outer layer of our steriliser box. However, as we construct our prototype, we realised that using plastic sheets may not be ideal as it makes the wall of the box flimsy and it may not be able to support the weight of the phone. Therefore, laser-cutting was a last minute decision to improve on the aesthetics and the sturdiness of our sterilizer box.

We decided to create a casing for the sterilizer box by surrounding the outer surface of the sterilizer with acrylic.

One thing we could have done better is to create slots so that it will make a perfect, tight-fitting acrylic box instead of pasting the acrylic together with got glue gun.

Hero shot of me working on CorelDraw!

Part 5. Integration of all parts and electronics (Done by ALL)

i. 3D Printed Components

We created holes at the bottom of the hinged lid as well as at the base of the box. Skewers with fairy lights wrapped around, were used to connect both the lid and the base.

ii. Weight Sensor

The weight sensor we are using is a 5kg load cell with a HX711 amplifier sensor

The output signal produced by the load cell is in range of millivolts, so we need an amplifier to convert the signal into a level that we can later transform it into a digital signal and process it. For this purpose, we use HX711 amplifier sensor. It includes a HX711 chip with analog-to-digital conversion capability in 24-bit accuracy. The HX711 module amplifies the low-voltage output of the load cell and sends it to the Arduino so that the Arduino eventually calculate weight from this data. The load cell is a transducer which converts force into measurable electrical output.

iii. Connection

After soldering our wires, we connected our weight sensor and fairy lights to the Arduino Uno as shown below.

Load cell To Arduino Uno Fairy Light

Red -> E+ GND>GND Red -> GND

Black -> E- VCC>5V Blue -> PIN 13

Green -> A- DT> PIN 3

White -> A+ SCK>PIN 2

iv. Laser Cut Component

The acrylic sheets that we cut out would be used for the outer walls of our product.

v. Assemble

Materials involved:

Soldered weight sensor and fairy light

3D printed parts

Skewers

Reflective sheets

Clear board

Outer walls of the product (Laser Cutting)

Steps to assemble:

Connect the base and the lid using skewers

Slot the weight sensor beneath the base and wrap the wire of fairy lights around the skewers

Paste the reflective sheet onto a clear cupboard and stick it outside the box

Take the laser cut black opaque acrylic sheets, and cover the exterior of the product with it entirely

Hero Shots for Integration!

4. Problems and Solutions

As we construct our product, we faced some difficulties. Firstly, one of the problems faced was when we tried to code using the Arduino board. We took a long time to search for the source codes as we wanted to obtain an accurate calibration factor. Unfortunately, majority of the source codes we found online either did not work or was not suitable for our weight sensor. In addition, we found out that our jumper wires were the main reason why our codes were not successfully uploaded to the Arduino board as they were faulty and no current was flowing through it. After multiple attempts and research, we managed to find a source code that works and once we replaced the wires, we were finally able to calibrate the weight sensor.

Another problem faced was, during our design process, we had planned to incorporate an adjustable clasp mechanism for the sterilisation box to fit a variety of phone models. However, due to the complexity and size constraint (as we minimised our prototype), we had to think of an alternate way to hold the phone upright while it is being sanitised. Hence, we decided to keep it simple and included a trench at the bottom of the box that is wide enough to fit multiple phone thickness.

Finally, after spending long hours to 3D print our components, we tried to remove the support. However, excessive strength was used while attempting to remove the support for the hinge that connects the lid to the wall of the steriliser, causing it to break into 2 separate pieces. We had to schedule another day to reprint the components which was time-consuming. Our reprinted part was a success and despite the time crunch we were still able to stay on schedule.

5. Project Design Files

Here is the link to all of our Project Design Files:

With that, my CPDD journey has came to an end! 🥳🎉🎆🧨 Thank you for reading my blog as always, goodbye! ʕ•́ᴥ•̀ʔっ

Comments